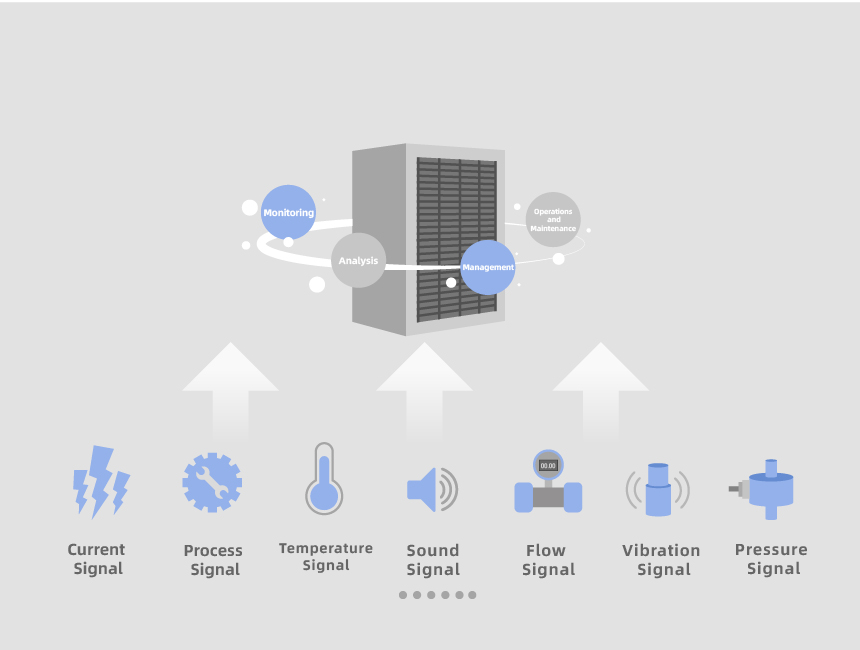

Our acoustic holography combined with AI technology enables intelligent sound detection by monitoring sound signals in real time for smart analysis and processing. It automatically identifies the type and location of different sound sources, quickly and accurately analyzing the characteristics and content of the sound signals. This not only significantly reduces manual workload but also improves detection accuracy and efficiency.

-

Equipment Fault Detection

By extracting and analyzing noise, we conduct location-based, quantitative, and qualitative fault diagnosis of equipment, effectively reducing the failure rate and maintenance costs of monitored devices, extending their lifecycle, and improving overall production efficiency.

High Precision and Non-Contact

Strong Penetration Power

Reduced Maintenance Costs

-

Finished Product Quality Inspection

This complements our intelligent visual surface quality inspection solutions, providing smart quality checks for movable parts and complex internal structures through changes in acoustic signals.

Quality Inspection Accuracy > 99%

High Detection Sensitivity

Multi-Dimensional Detection

Rapid Response Capability

The deployment of sound signal collection and analysis can be completed within 7-14 days on-site, with the overall solution delivered within 45 days.

High-Efficiency Computing

Our proprietary acoustic holography combined with AI technology enables simultaneous data collection and computation, thereby enhancing overall computing efficiency.

Fault Recognition Optimization

We calibrate, compare, and match fault data to train deep learning and ensemble learning algorithm models, enhancing the effectiveness of fault recognition.

Strong Versatility

The extraction of sound features is applicable to any scenario and device, allowing the solution to be deployed across industries, environments, and machinery.

Contact Us

Contact Us