high-end intelligent earphone production

monthly capacity

We have information management systems such as Data Center, QingFlow, Teambition, MES, CRM, Order Review, Kingdee, and OA. These systems enable the recording and management of every production action, allowing real-time tracking of every step of the product process to enhance production efficiency and quality.

We have established various specialized laboratories, including acoustics, environmental, comprehensive, and electrostatic testing laboratories. With a complete set of experimental procedures and over 100 reliability testing projects, we strictly control and ensure the quality and stability of our products, striving to offer our customers higher-end and superior quality solutions.

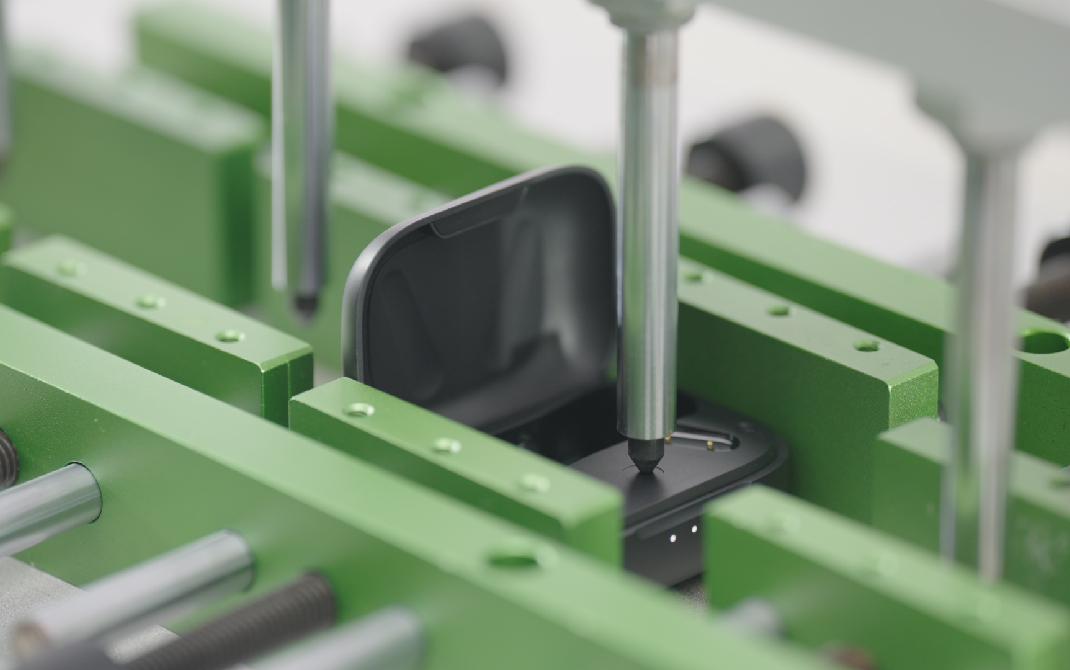

Semi-finished product

Mainly includes software burning, functional testing and audio performance.

Software flashing

Software flashing

Functional testing

Functional testing

Audio performance

Audio performance

Finished product

Multi-faceted quantitative testing in the trial production stage, mainly including software, acoustics, RF, actual experience, battery, etc.

Software testing

Software testing

Acoustic testing

Acoustic testing

Real experience testing

Real experience testing

Battery performance

Battery performance

RF parameters

RF parameters

Pull distance testing

Pull distance testing

Reliability testing

Reliability testing

Touch Sensor testing

Touch Sensor testing

Packing information

Packing information

We have established multiple quality management systems and strictly adheres to target quality standards during production. We control and inspect every stage of the manufacturing process to ensure high-quality products that meet the stringent demands of domestic and international manufacturers.

AncSonic maintains close communication and collaboration with suppliers and downstream partners to comprehensively enhance supply chain management efficiency and effectiveness. This approach ensures timely delivery and quality assurance of materials while further reducing material, production, and operational costs. These efforts are aimed at meeting customer demands for pricing, capacity, quality, and delivery timelines.

01

Demand Planning

02

Procurement Management

03

Supplier Management

04

Sourcing Management

05

Financial Management

06

Production Planning

07

Material Planning

08

Inventory Management

09

Logistics Management

10

Delivery Data

Contact Now

Contact Now